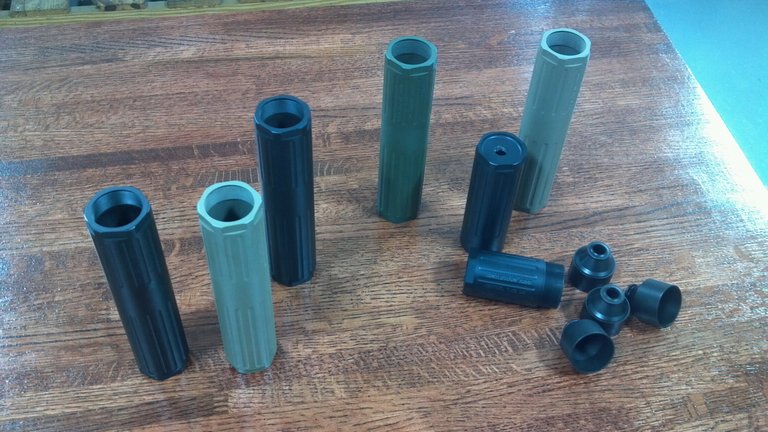

Up until now, user serviceable centerfire rifle suppressors have been longer and heavier than their sealed counterparts. That's changed with the introduction of the Kestrel 5.56. Engineered from the ground up to maximize serviceability while not compromising on weight, length, or strength, the Kestrel 556 provides the most user friendly centerfire rifle suppressor in existence. Whether you are looking for outstanding suppression, safety, ease of maintenance, weight, length, longevity, or price, the Kestrel 5.56 has the features you are looking for. Suppression The Kestrel 5.56 had one goal - provide a hearing safe centerfire rifle suppressor that can be easily maintained and repaired. It does not disappoint. Maintenance Cleaning the Kestrel 5.56 is a breeze. Centerfire rifle suppressors need to be cleaned and inspected, just like rimfire suppressors. With the Kestrel 5.56 full user servicability is truely a reality. The Kestrel core is constructed of stainless steel for superior cleanability. You can use chemical solutions safe to stainless steel but that remove nasty lead deposits (the "Dip"). The core breaks down so that you can put it into a reloading tumbler, or use a bead blaster for fast and efficient cleaning. And unlike other monocore technologies, you can dip your Kestrel core without worrying about damaging the exposed finish on your core. Kestrel baffles are fully encased for superior strength and to prevent lead and carbon buildup between the core and the tube, even after thousands of rounds fired. This provides for quick and easy removal of your Kestrel core, without the hassle or need of pushers or other devices to remove it. And as with all Huntertown Arms suppressors, all it takes to remove your end caps is a standard, box end, or crescent wrench, a bench vise, pair of pliers, or any other tool that can grab a standard socket. No special tools required. Ever. Longevity There are several features designed into the Kestrel to ensure your safe and enjoyable use of the Kestrel beyond a lifetime. Most bullet strikes on a suppressor occur on the end cap. The Kestrel design separates the end cap from the registered part so that if there is an end cap strike it will be more likely your suppressor can be repaired or replaced without having to replace the registered part. We are huge proponents of stacked bafle technology for another reason. With a monocore, there is only one blast baffle. When that blast baffle erodes, the core has to be replaced. This may or may not be a warranty repair, but in any event you have lost the use of your suppressor while it is at the manufacturer for repair. Kestrel core baffles should be rotated (like tires) whenever the core is cleaned. With four baffles available to act as blast baffles, the Kestrel will allow up to five times the number of rounds fired before re-coring. Safety The Kestrel core is fully encased in an inner stainless steel wall. In the event of an internal baffle strike, the inner core is strong enough to capture the damaged projectile and baffle material, protecting the tube as much as possible against catastrophic failure. |

Specifications

|